Dynamic Positioning Systems

This page gives an overview of Dynamic Positioning (DP) systems. Please see the DP Policy & Guidance and DP Voluntary Reporting pages for additional regulatory information.

For additional, detailed information and references, please see the Introduction to Dynamic Positioning (DP) Systems guide.

Use the tabs above to view content related to the following topics:

- DP Sub-Systems;

- Classes of DP Systems (Class 1, Class 2 and Class 3 information/design criteria);

- Reference Systems (position, environment and motion);

- DP Operator (DPO);

- DP Operations Manual;

- DP System Plan Review and Approval; and

- DP Verification (Surveys, Tests and DP Verification Acceptance Document)

Uses of DP Systems on the OCS

A Dynamic Positioning System is a computer-controlled system used to automatically maintain a vessel’s heading and position without the use of mooring lines and/or anchors.

Since it was first introduced in the 1960s, DP Systems have evolved to become the primary means of station keeping for vessels operating on the U.S. Outer Continental Shelf (OCS). DP Systems are often used on Mobile Offshore Drilling Units (MODUs), Floating Production Units (FPUs), Construction Vessels, Accommodation Vessels (Floatels), Dive Support Vessels, Offshore Supply Vessels (OSVs), cable and pipe-laying vessels and shuttle tankers.

The DP system is used to maintain the vessel’s position in order to conduct critical activities such as drilling, diving operations, under water construction, and close quarter activities such as bulk cargo transfers, fuel transfers, deck cargo operations, personnel transfers, and ROV work.

DP Sub-Systems

A DP System is comprised of three sub-systems:

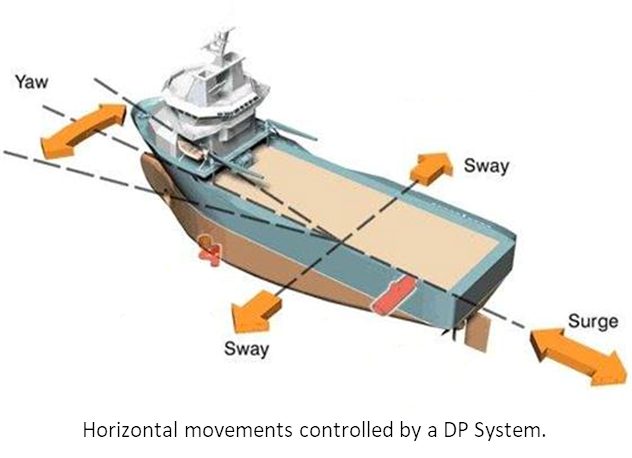

These three sub-systems work in unison to maintain the vessel’s heading and position by controlling the horizontal movement of the vessel.

Power System

The power system is comprised of all components and associated systems necessary to supply the DP system with power.

The power system includes but is not limited to:

- prime movers;

- generators;

- switchboards;

- distribution systems (associated cabling and cable routing);

- uninterruptible power supplies (UPS) and batteries; and,

- power management system(s) (as appropriate)

The power supply should be reliable and adequate to provide continuous power to the DP control system, thrusters/propulsion systems and all of the vessel’s other operational loads or power demands so that the DP system can maintain the vessel’s desired position and heading.

Thruster System

The thruster system is comprised of all components and associated systems necessary to supply the DP system with variable force and direction of thrust.

The thruster system includes:

- thrusters with drive units and necessary auxiliary systems including piping, cooling, hydraulic and lubrication systems, etc;

- main propulsion systems; propellers and rudders, Z-drives, azipods, water jets, etc;

- auxiliary thrusters; tunnel thrusters, drop down thrusters, z-drives, etc;

- thruster control systems;

- manual thruster controls; and,

- associated cabling and cable routing.

The thruster system shall be arranged as to provide the vessel with adequate maneuverability under all operating conditions. Also, the thruster system should be able to provide adequate thrust to control surge, sway and yawing.

Thruster systems should be arranged so that the failure of any part of the system including pitch, azimuth or speed control should not increase the thrust magnitude or direction.

Individual thruster emergency stop systems should be arranged in the DP control station.

DP Control System

The DP control system is comprised of all control components and associated systems, hardware and software necessary to coordinate with the other sub-systems to maintain position.

The DP control system includes:

- computer system;

- joystick system;

- sensor system(s);

- control stations and display system (operator panels);

- position reference system(s);

- associated cabling and cable routing; and,

- networks.

The control computers receive input from various sensors and reference systems to determine the vessel’s heading, position and the external forces being applied to the vessel. This information is then processed to determine the amount and direction of force that must be applied in order to counteract the external forces. The Power and Thrust sub-systems then execute the commands given from the control system and exerts the desired force needed to maintain the desired heading and position.

Classes of DP Systems

The IMO has categorized DP Systems into three equipment classes based on redundancy and protection. The necessary redundancy level for the components and systems are determined by the consequence of the loss of vessel position and/or heading.

The classes are stated below as defined in IMO MSC.1/Circ. 1580:

Class 1

A loss of position and/or heading may occur in the event of a single fault.

Class 2

- A loss of position and/or heading will not occur in the event of a single fault in any active component or system.

- Single failure criteria include, but are not limited to:

- Any active component or system (generators, thrusters, switchboards, communication networks, remote-controlled valves, etc.); and,

- Any normally static component (cables, pipes, manual valves, etc.) that may immediately affect position keeping capabilities upon failure or is not properly documented with respect to protection.

- Common static components may be accepted in systems which will not immediately affect position keeping capabilities upon failure (e.g. ventilation and seawater systems not directly cooling running machinery).

- Normally such static components will not be considered to fail where adequate protection from damage is demonstrated to the satisfaction of the Administration.

Class 3

- A loss of position and/or heading will not occur in the event of a single fault or failure.

- A single failure includes:

- Items listed above for class 2, and any normally static component assumed to fail;

- All components in any one watertight compartment, from fire or flooding; and

- All components in any one fire sub-division, from fire or flooding (for cables, see also paragraph 3.5.1 of IMO MSC.1/Circ. 1580).

Position Reference Systems

In order for the DP System to keep a vessel in a desired position, it must utilize a Position Reference System (PRS). The PRS identifies the vessel’s current position. This position will either be an absolute position (geographic position) or a relative position (relative to a target).

There are several systems, which utilize either absolute or relative positions. Some of these systems and some common brand names are:

Relative: Laser (Cyscan®, Fanbeam®), Microwave (Radascan®), and Tautwire

Absolute: Satellite (DGPS, DGNSS), and Underwater Acoustics (HPR)

When two or more position reference systems are used or required, they should not be of the same type, and should be based on different principles and suitable for the operating conditions.

Environmental & Motion Sensors

Vessel should be equipped with sensors to measure heading, vessel motion and the wind speed and direction.

These sensors include:

Gyro: The gyrocompass constantly provides the DP computer with the vessel’s current heading data in order to maintain and/or control vessel’s heading.

Wind: Input from wind sensors are needed for the controller to measure the effects of the wind on the sail area of the vessel.

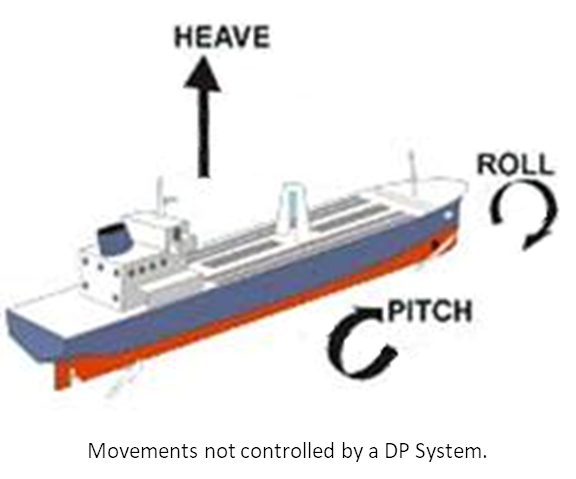

Motion Sensors: These sensors measure 3 of the 6 degree of motions that are not controlled, but must be accounted for to improve accuracy of the position reference systems.

- Pitch (rock fore and aft),

- Roll (rock side to side)

- Heave (lift up and down)

Sensors for the same purpose which are connected to redundant systems should be arranged independently so that failure of one will not affect the others. Example: the three gyrocompasses that are providing input data into the two DP computers should be arranged that failure of one gyrocompass shall not affect the remaining two gyros.

Human Element (DP Operator)

The DP operator should be:

- A navigational watch officer

- Trained and experienced

- Knowledgeable and familiar with the DP system and vessel’s characteristics

- Responsible for the input of the desired position and heading into the DP computer

- Responsible for monitoring all systems to ensure safe, effective and efficient DP Operations, including:

- weather

- positioning capability

- DP control systems

- power systems

- thrusters systems

- any other systems relevant to DP Operations.

The required training, familiarization and/or certification of the DP personnel on board will be included in the approved DP Operations Manual.

DP Operations Manual

A DP Operations Manual is required as part of the plan review and approval. The DP Operations Manual should be vessel specific and located near the DP Operator’s Station, readily available to the DPO for quick reference during DP Operations. DP operations should be conducted in accordance with the approved DP Operations Manual.

DP Operations may be considered “Key Shipboard Operations” as stated in Regulation 7 of International Safety Management (ISM) Code. Therefore, the DP Operations Manual may also be part of the vessel’s Safety Management System (SMS).

The requirement for the vessel specific DP Operations Manual is in addition to the manufacturer’s Owner’s or Operator’s Manual.

The requirements for the contents of the DP Operations Manual differ depending on the approving authority. However, most DP Operations Manual will normally include the items listed below:

- Vessel Specific DP Operation Instructions: The manual should be representative of the way the vessel is operated in DP. It may also include Company Specific Policies and Procedures regarding Operations and Reporting.

- On-site Location and Watch-keeping Checklists: Checklists specific to the on-site location as well as watch-keeping should be included in the DP Operation’s Manual. These checklist usually include both bridge and engine room checklists.

- DP Personnel Training and Competence Requirements: The Operations Manual should provide requirements for training and competence of all DP personnel. This may include: on board familiarization, training certifications, checklists and assessments.

- Weather and Operation Limitations: The DP Operations Manual should include information related to the limitation of DP Operations with regards to; weather, power systems, thrusters, proximity to other vessels/MODUs/structures, draft, simultaneous operations (SIMOPS), preventative maintenance, etc.

- Capability Plots: The DP Operations Manual may also include Capability Plots which are calculated 360 degree envelopes of current and wind speeds that the vessel can theoretically be able to maintain position in certain scenarios. These scenarios would include; intact power and thrusters, loss of most effective thrusters, and following a worst case failure (WCF). Although, capability plots may be included in the approved DP Operations Manual, they may also be in a separate folder for quicker access during DP Operations.

- Foot Print Plots: Foot Print Plots are actually taken onboard, to measure the vessel’s performance while on DP within an established time period. The DP Operations Manual should include instructions on when these plots should be taken and include a sample form. These plots are normally completed manually, but may be done electronically if the DP Operator Station has the capability.

- Incident/Accident Reporting: Incident/Accident reporting requirements should be included in the DP Operations Manual. There may also be instructions for reporting requirements for change of status when using an Activity Specific Operating Guidelines (ASOG)/Well Specific Operating Guidelines (WSOG) or Critical Activity Mode of Operations (CAMO).

- Record Keeping: The DP Operations Manual should also contain instructions for record keeping. DP related records should be maintained onboard and, where appropriate, at the company’s office.

- Operational Planning: The DP Operations Manual should include specific guidance in the form of an ASOG/WSOG and CAMOs for specific DP activities and missions, as appropriate. The DP Operations Manual should also give the configuration arrangement of the vessel’s DP system for Task Appropriate Modes (TAMs), and Critical Activity Modes (CAMs).

- List of Critical Components: A list of critical components should be identified and listed in the DP Operations Manual.

- Blackout Recovery: There should be blackout recovery procedures in the DP Operations Manual to provide guidance for recovery in the event of a blackout.

DP System Plan Review and Approval

For U.S. Flagged vessels, the DP System’s Plans and Documents should be approved by the U.S. Coast Guard’s Marine Safety Center (MSC) or an Authorized Classification Society (ACS)/Responsible Organization (RO) on behalf of the Coast Guard. Evidence of approval will be a copy of stamped Plans/Documents, and Reviewed/Approved Letter from the approving authority. There should also be records of the completed Proving Trials on board that should be stamped reviewed/approved.

DP Documents that should be reviewed and approved are:

- DP Failure Modes and Effects Analysis (FMEA)

- DP Proving Trials

- Special Trials (when applicable)

- Operations Manual

The Marine Safety Center oversees plan review and other technical work performed by ACS/ROs for U.S. Flagged vessels and has published several guidance documents regarding the review and approval of plans for DP systems. Two of them that are commonly known and used are MSC’s MTN 02-11, CH-1 and PRG E2-24.

Marine Safety Center MTN 02-11, CH-1

The Marine Safety Center has published a Technical Note for DP Plan Submittal and Approval (MSC’s MTN 02-11, CH-1) which provides guidance for submitting plans to the MSC, or to an ACS conducting review of these systems on behalf of the Coast Guard. Enclosure (2) of the MTN allows the submitters to submit plans using the IMO MSC/Circular 645 Guidelines for vessels with DP Systems as the baseline for the design, or cite the relevant Classification Society Rules for the design.

Marine Safety Center PRG E2-24

In addition to MTN 02-11, the Plan Review Guideline (PRG) E2-24 titled “Review of Dynamic Positioning Systems” will assist the plan submitters with preparing and submitting a DP system plan to the Marine Safety Center.

Surveys, Tests & DP Verification Acceptance Document

DP Failure Modes and Effects Analysis (FMEA)

A FMEA is a systematic analysis of systems and sub-systems to a level of detail that identifies all potential failure modes down to the appropriate sub-system level and their consequences.

- Required for DP Classes 2 & 3.

- Should be carried out to demonstrate that no single failure will cause a loss of position or heading and should also verify worst-case failure design intent.

- The DP components and systems on board the vessel should match the components and systems that are listed in the approved FMEA.

- Should be kept on board and should be kept updated so that it remains current.

- Should be approved by flag state or their recognized ACS/RO (For U.S. Flagged vessels, the FMEA will be approved by the Marine Safety Center or an ACS/RO).

DP Proving Trials

A survey and proving trials should be conducted to confirm the expected effects of the failure modes found in the FMEA desktop analysis.

- Required for DP Classes 2 & 3.

- Should test the interface of the different systems and equipment of the different vendors.

- Proving Trials test to confirm that no single fault will cause a loss of position or heading and will also verify worst-case failure analysis.

- The test procedures and the results of the DP proving trials should be kept on board.

- Should be approved by the flag state or their recognized ACS/RO. For U.S. Flagged vessels, the Proving Trials will be approved by the Marine Safety Center or an ACS/RO.

- These tests are comparable to the U.S. Regulatory requirements for Design Verification Test Procedures.

DP Periodic Trials

A survey and periodic trials should be completed every 5 years using similar test procedures as the DP Proving Trials.

- Required for DP Classes 2 & 3.

- Tests should confirm that system continues to operate as designed and no single fault will cause a loss of position or heading and will also verify worst-case failure analysis.

- The test procedures and the results of the periodic trials should be kept on board.

DP Annual Trials

The annual survey and tests of the DP system and components should be completed within 3 months before or after the anniversary date of the DPVAD or initial survey.

- Required for DP Classes 2 & 3.

- Verifies that the DP system is able to function as designed and also validates the FMEA and operations manual.

- Annual Trials are usually more limited in scope and are comparative to that of the Regulatory requirements of the Periodic Safety Test Procedures.

- The test procedures and the results of the annual trials should be kept on board.

Special Trials

Either a general or partial survey and test, depending on the circumstances, should be carried out each time a defect is discovered and corrected or after an accident occurs which affects the safety of the DP vessel, or whenever any significant repairs or alterations are made.

- Any changes, upgrades, or modifications (excluding in-kind changes) to components or systems listed in the FMEA, including software changes, must be resubmitted to the Marine Safety Center and/or an ACS/RO for approval and be tested.

- The tests procedures and the results of the special trials should be kept on board.

- Should be approved by flag state or their recognized ACS/RO.

- For U.S. Flagged vessels, these tests will be approved by the Marine Safety Center or an ACS/RO.

Dynamic Positioning Verification Acceptance Document (DPVAD)

This document should be issued by the Flag State or RO to vessels that comply with the IMO DP guidance (IMO Circ.645 or Circ.1580), as applicable.

- Should be issued for a period not to exceed 5 years

- Should cease to be valid if significant alterations have been made to the DP system or components without Administration or RO approval.

Note: Because the U.S. Coast Guard does not have any regulations regarding DP systems, DPVADs are not normally found on U.S. Flagged vessels. Verification of DP systems would be found on the appropriate Classification Certificate.