Types of Floating OCS Facilities

See also Drill Down Issue #5 for related information.

Floating OCS Facilities (FOFs), also historically referred to as Floating Offshore Installations (FOIs), vary in the types of designs that are in service. In this article, we'll look at the various designs associated with the FOFs that are typically seen on the U.S. Outer Continental Shelf (currently only in the Gulf of Mexico).

33 CFR 106 is applicable if the facility has 150 people onboard for 12 hours or more in each 24-hour period continuously for 30 days or more, or it produces greater than 100,000 barrels of oil per day, or produces greater than 200 million cubic feet of natural gas per day.

Tension Leg Platforms (TLPs)

Tension Leg Platforms (TLPs)

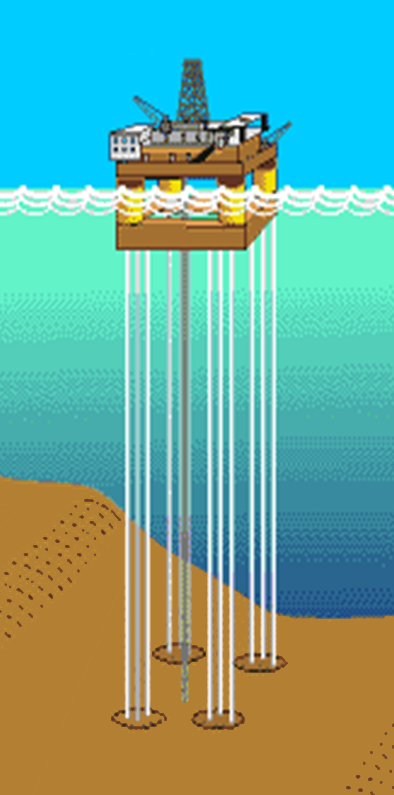

TLPs are vertically-moored, column-stabilized oil and gas production units. The columns are connected by pontoons at the bottom of each column and the topsides are placed on the column tops.

They are held in place by pipe-like “tendons” under significant tension to mooring pilings installed into the seabed. The tension is held on the unit by excess buoyancy in the hulls (also known as columns). Ballast (seawater) in the hulls can be added, moved or removed to adjust the tension as needed. The tension that is maintained on the facility limits the horizontal movements and prevents vertical (heave) movements. The number of tendons can vary based on the size of the facility, environment and design.

Three TLP hull designs are commonly used on the U.S. OCS: conventional (large), MODEC's MOSES (Minimum Offshore Surface Equipment Structure) and SeaStar.

TLPs are generally limited to water depths of 6,000 feet and less.

Column-Stabilized Units (Semi-Submersibles)

Column-Stabilized Units (Semi-Submersibles)

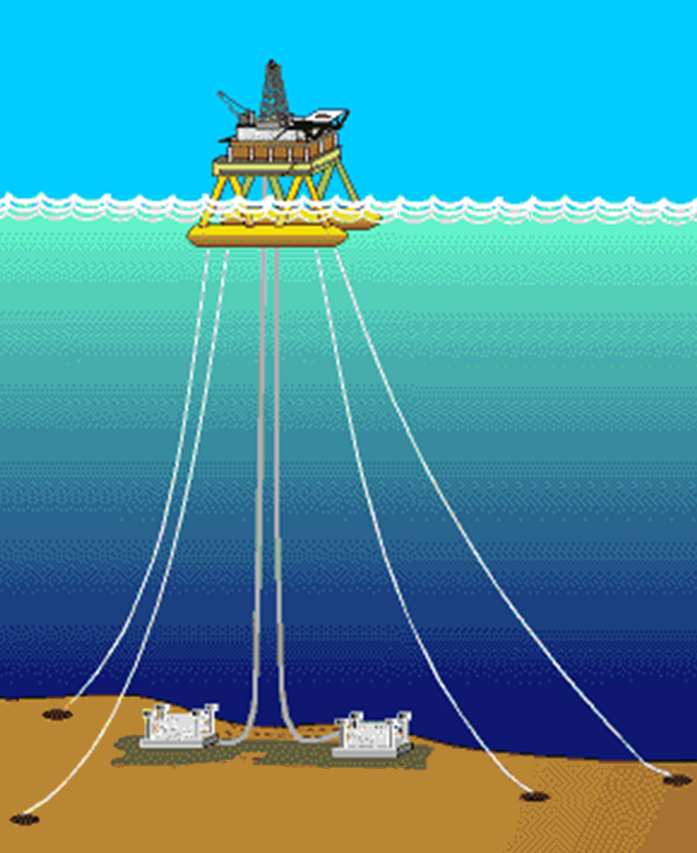

A semi-submersible looks very similar to the TLP. They are column-stabilized with the columns connected by pontoons at the bottom and the topsides are placed on top of the columns tops like the TLPs.

The major difference is that they are free-floating and held in place with moorings attached to seabed mooring piles, normally consisting of a coated cable or synthetic line with chain at both ends. The tension in the moorings from the catenary in the cables/synthetic line limits movement of the unit.

Semi-submersibles have been installed in water depths of 1,000 feet and greater.

Spars

Spars

The Spar has one long cylindrical hull (Classic Spar; left) or a cylindrical hull and open truss structure (Truss Spar; right) that extends several hundred feet into the sea. At the bottom of the hull, or truss, is a permanent ballast tank that is filled with a material (liquid slurry) that is denser than the surrounding water. This material and tank are used to lower the center of gravity for improved stability.

The hull is encircled with helical strakes that limit the formation of vortices from the flow of water around the cylindrical hull that would otherwise cause the spar to surge and sway.

Spars are attached to the seafloor utilizing moorings attached to seabed mooring piles, normally consisting of a coated cable or synthetic line with chain at both ends. This design and mooring system will allow some lateral and rotational movement and will keep the vertical movement nominal.

Spars have been installed in water depths ranging from over 1,500 feet to nearly 10,000 feet.